Enhancing DP Level Measurement Accuracy with Yokogawa’s Compensating Capillary System

Enhancing DP Level Measurement Accuracy with Yokogawa’s Compensating Capillary System

Accurate level measurement is vital in process industries, particularly when dealing with chemicals stored in pressurized or sealed tanks. Differential Pressure (DP) transmitters, equipped with remote diaphragm seals, are commonly used for this purpose. However, temperature fluctuations can significantly impact the accuracy of these measurements due to the thermal expansion or contraction of the fill fluid within the capillaries.

The Challenge of Temperature Variations

In outdoor installations, ambient temperatures can vary widely. For instance, in the UK, wide daily temperature variances are not uncommon. Such variations can cause the fill fluid in the capillaries to expand or contract, leading to erroneous DP readings. This inaccuracy can result in overfilling or underfilling tanks, posing safety risks, potential environmental hazards, and operational inefficiencies.

DP-Flow Ltd's Innovative Solution: The Yokogawa Compensating Capillary

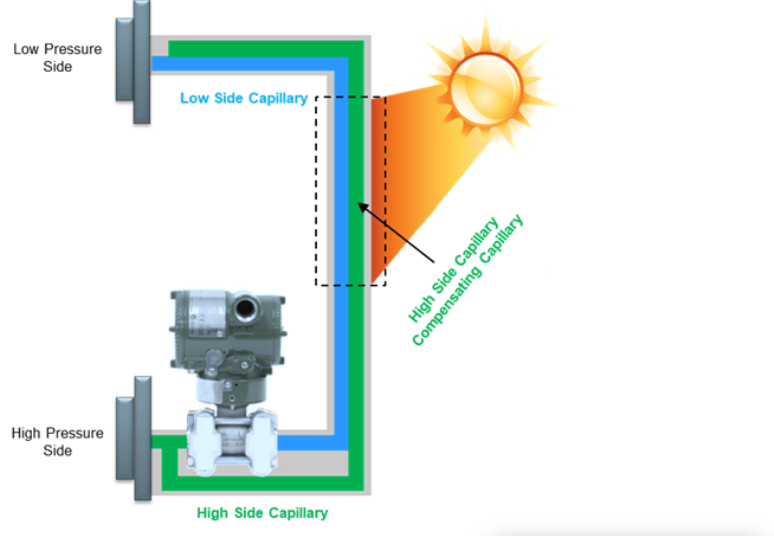

To address this challenge, Yokogawa developed the Compensating Capillary system. This design introduces a "dummy" capillary on the high-pressure side of the transmitter, mirroring the low-pressure side's capillary. By running both capillaries in close proximity, they are exposed to the same temperature conditions. This setup ensures that any temperature-induced changes in the fill fluid's volume affect both sides equally, effectively canceling out the temperature-related errors in the DP measurement.

Key Benefits of the Compensating Capillary System

Improved Measurement Accuracy: By mitigating temperature-induced errors, the system provides more reliable level readings.

Reduced Maintenance: The design minimizes the need for frequent recalibration, lowering operational expenses.

Enhanced Safety: Accurate level measurements help prevent overfills and equipment damage, ensuring safer operations.

Ideal Applications

This system is particularly beneficial in industries such as:

Chemical Processing: Where precise level measurement is crucial for safety and product quality.

Petrochemicals and Refining: Where tanks are often exposed to varying environmental conditions.

Pulp & Paper: Where consistent level monitoring is essential for process efficiency.

Conclusion

DP-Flow Ltd's Yokogawa Compensating Capillary system offers a practical and effective solution to the challenges posed by temperature variations in DP level measurements. By ensuring accurate and reliable readings, it enhances operational safety and efficiency across various industries.