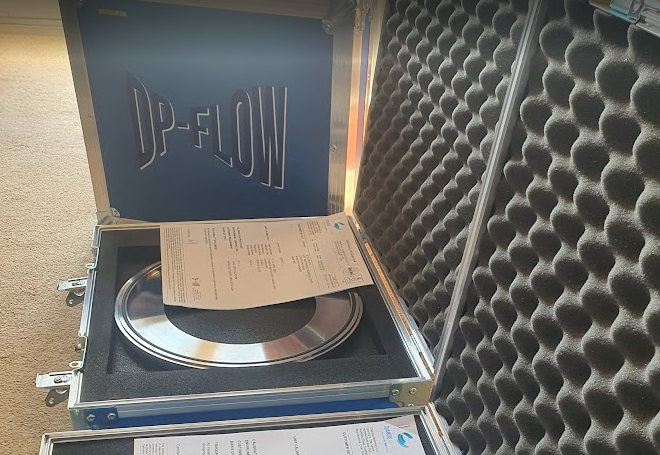

Orifice Plates with Integral Seals

The Future of Sealing: DP-Flow Ltd's Integral O-Ring Seal Redefines Performance Standards

In the world of flow measurement, ensuring a reliable seal around orifice plates has always been a critical factor in maintaining system integrity and accuracy. For years, bonded seals have been the industry standard — but now, DP-Flow Ltd’s new orifice plate design with an integral recessed O-ring seal is setting a higher benchmark for performance.

Unlike traditional bonded seals, which rely on a fixed elastomer bonded to a metal orifice plate, the DP-Flow Ltd integral O-ring design incorporates a recessed groove machined directly into the orifice plate itself. This groove houses a precision-fitted O-ring, creating a dynamic seal that responds more effectively to system pressure and thermal expansion.

Key Improvements Over Bonded Seals:

Superior Seal Integrity: The O-ring maintains continuous pressure against sealing surfaces, even under thermal cycling and high-pressure fluctuations, reducing the risk of leaks.

Easier Maintenance and Replacement: O-rings can be quickly replaced without needing to discard or rework metal components, saving time and cost during maintenance.

Enhanced Durability: The recessed design protects the O-ring from over-compression and mechanical damage, significantly extending the service life compared to bonded seals.

Improved Alignment and Fit: The integral seal ensures precise seating of the orifice plate, minimizing measurement errors caused by misalignment or uneven sealing.

The new DP-Flow Ltd orifice plate with integral recessed O-ring seals isn't just an upgrade — it's the new standard for bonded seal replacement. It delivers better sealing performance, greater longevity, and easier maintenance, raising the bar for reliability in critical measurement systems.

Welcome to the next generation of orifice plate technology.